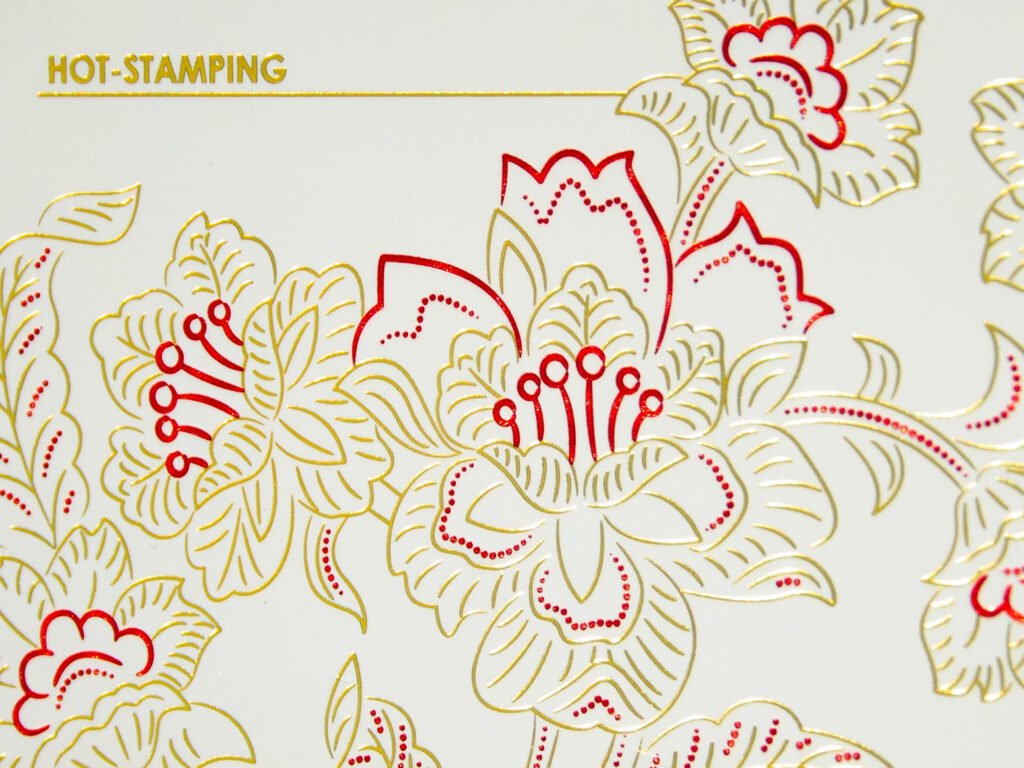

Hot Stamping Techniques

Hot stamping, RP Texture Hot Stamping, and 3D Hot Stamping are the versatile and sophisticated printing techniques that involve applying heat and pressure to a metallic, matte, gloosy, or colored foil, results in a luxurious and eye-catching finish.

In KIMI Hot Stamping, we can help to make your prints visually appealing, and it is durable and resistant to wear, making it suitable for various applications, including product packaging, labels, and promotional materials.

Businesses use hot stamping to imprint logos, names, and other branding elements on various promotional materials. It is is popular for adding a touch of sophistication to book covers, notebooks, red packets, and high-end stationery.

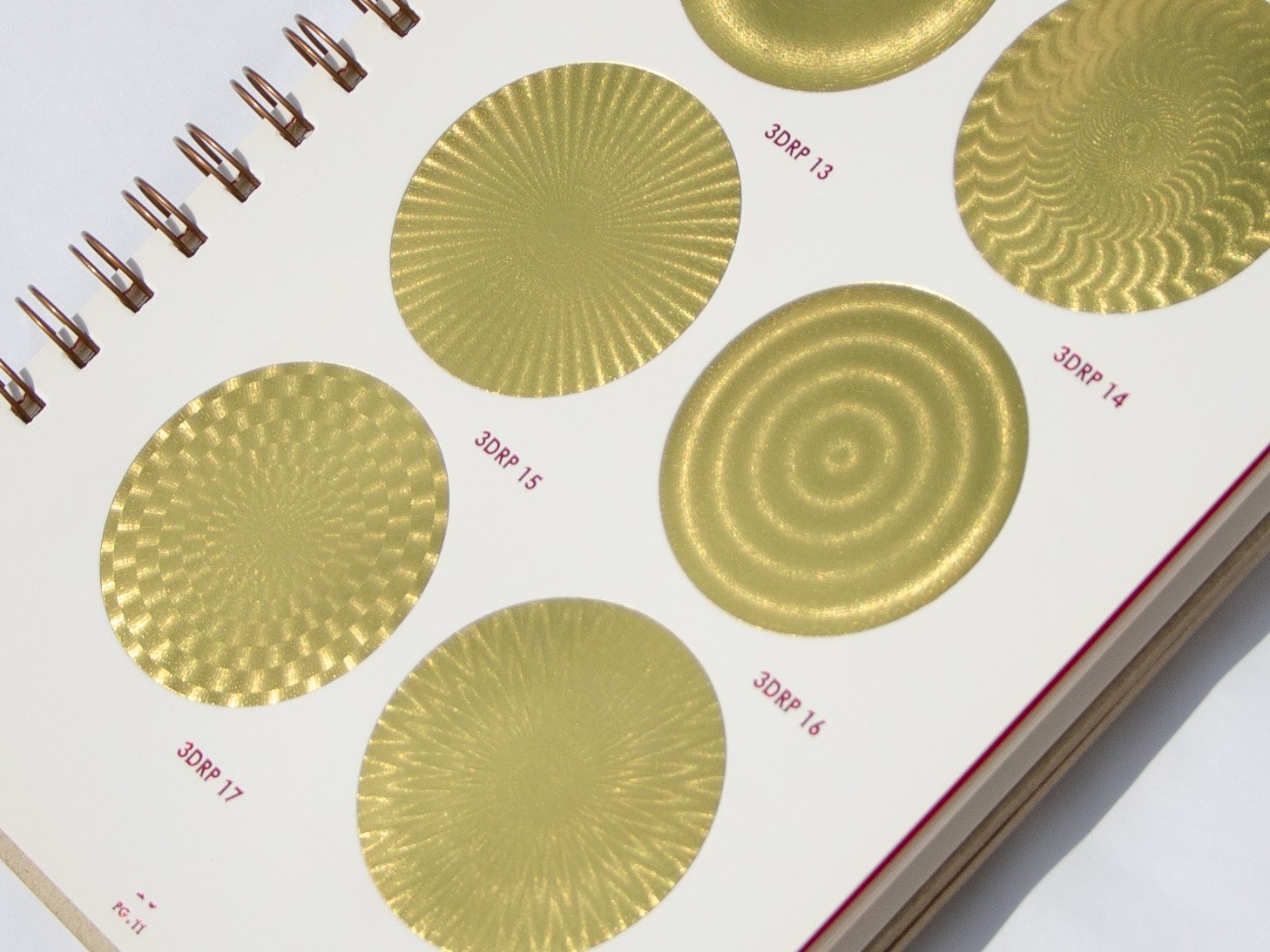

What is a 3D Hot Stamping?

Three perfectly matched parts are needed for the 3D Hot Stamping (3DHS) coating process:

- 3DHS hot stamp machine

- 3DHS die system

- unique hot stamping foil.

The hot stamping foil is specifically designed to fulfill the demands of three-dimensional embellishment. Because of its high elasticity, it can be thermally shaped in a work operation before the stamping process to match the geometry of the plastic part.

The primary benefit of 3DHS is to prevent wrinkles. In the past, a part's outer ring could often only be decorated by a designer if the part geometry was flat and constant. Wrinkles can become a problem in traditional hot stamping if the part geometry is not intended for a proper hot stamp; however, with the 3DHS process, the vacuum and the flexibility of the foil minimize that worry.

Supported Paper Size

- 25" X 37"

- 22" X 52"

- 25" X 35"

- 22" X 32"

- 18" X 23"

- 16" X 20"

- 10" X 15"

- 8.5" X 12"

- 2.5" X 3.5"